OKA ARCH BRIDGE SYSTEM PDF Brochure

The Innovative Precast Arch Bridge System

OKA Arch Bridge System ("ABS") is a buried arch system consisting of multiple SINGLE-PIECE precast reinforced concrete ARCH units that are placed together to form a complete bridge or underground structure. The precast arch units are either supported on strip footings founded on rock or piles or alternatively founded on continuous raft footing.

OKA Arch Bridge System offers a fast, cost effective and unrivalled aesthetic solution whether to replace an aging, deficient bridge; span a creek or river; build an underpass or tunnel for vehicular traffic.

The design of OKA Arch Bridge System is optimized taking full advantage of the arch's geometry and the soil-structure interaction that is made possible from a planned staged backfilling sequence.

|

APPLICATION

|

Multi-span ARCH

(Longer Span Structure) | | ● | Drainage Culvert | | ● | Pedestrian Underpass / Vehicular Underpass | | ● | Utility Tunnel | | ● | Storage Bunker | | ● | Underground storage structure | | ● | Single-Span for short to Medium Span Arch structure | | ● | Multi-Span Application for longer Span Arch Structure | | ● | Combined Application

for Pedestrian + Drainage + Vehicular Traffic |

Single-span ARCH

(Short to Medium Span Structure) | ADVANTAGES

| | ● | Aesthetically Pleasant | | ● | Fast Installation - Single-carriageway arch bridge can be installed in a day | | ● | Ease of Installation - Less labour required | | ● | Wide Clear Span - increase water flow velocity; free of debris accumulation problem at inlet that impedes flow and eventually causing blockage | | ● | No Expansion Joints - Maintenance free and very smooth ride; no deck maintenance problems | | ● | Short to Long Span Arch Bridge - single or multi-span arch bridge structure can be constructed with ease | | ● | Superior Strength and Durability - Precast arch units are manufactured using high strength concrete of low water/cement ratio that warrants durability requirements | | ● | Quality - Precast arch units are manufactured under controlled factory environment with stringent ISO 9001:2008 quality management system |

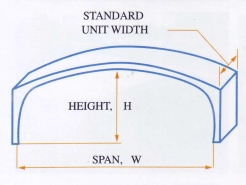

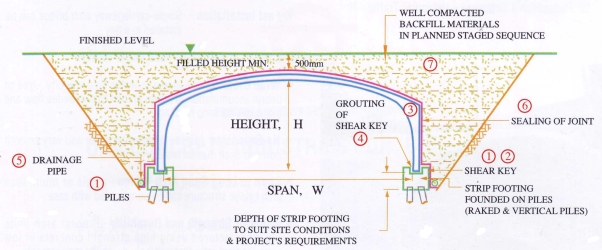

CONSTRUCTION SEQUENCES

| 1. | Preparation and construction of structural foundation to receive precast Arch units. |

| | | | Choice of foundation based on Engineer’s recommendations : | | | | (a) | Construction of 2 parallel cast in-situ strip footing with “shear key” (on top) on a combination of raked and vertical piles, OR | | | | (b) | Construction of 2 parallel cast in-situ strip footing with “shear key” (on top) on vertical piles and with in-situ horizontal tie-beams/slabs in between, OR | | | | (c) | Construction of 2 parallel cast in-situ “shear-key” on in-situ raft or pad footing. *Depth of strip footings depends on site conditions and Project’s requirements. | | | 2. | Levelling pads are set up at 1.2m centres along the “shear key”. |

| | 3. | Lifting and hoisting of precast ARCH units to sit into preformed "shear key" on pre-set levelling pads. | | 4. | Grouting of “shear-key” after placement of precast ARCH units. | | 5. | Install drainage pipes along buttom of ARCH wall on earth faces. | | 6. | Sealing of joints in between Arch units on the earth face using backer rod, cement mortar, geotextile or waterproofing material to Engineer’s approval. | | 7. | Backfilling with suitable materials approved by the Engineer to finished level In planned staged sequence. |

| TYPICAL METHOD OF CONSTRUCTION

(ARCH UNITS SIT ON STRIP FOOTINGS FOUNDED ON COMBINATION OF RAKED & VERTICAL PILES) |

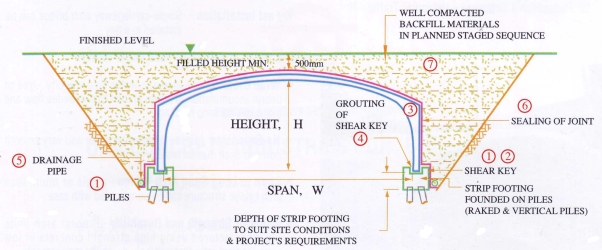

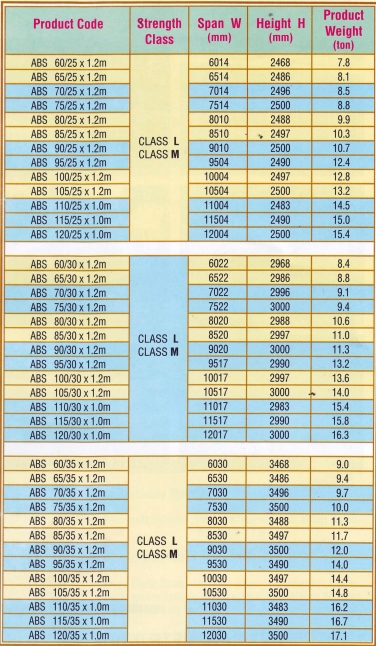

OKA STANDARD ARCH BRIDGE SYSTEM SECTIONS

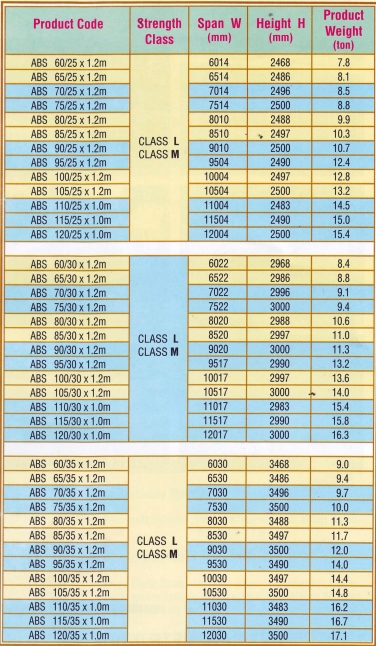

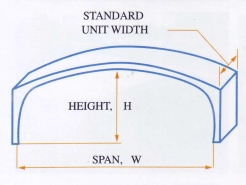

| ● | Nominal standard span available from 6.0m - 12.0m, at 500mm increment. |

| | ● | Standard width of 1200mm for arch unit span from 6.0m - 10.5m. | | ● | Width of 1000mm for arch unit span from 11.0m - 12.0m. | | ● | Internal height from 2.5m - 3.5m to suit site conditions. | | | | | | | | | |

| | | | | | | | | | | * | Class L :

Fill height from min. 500mm to 2000mm | | | | | * | Class M :

Fill height from 2001mm to 4000mm | | | | | * | Class H :

Fill height above 4000mm

(Special design subjected to site contions) | | | |

DESIGN CONSIDERATION

| ● | OKA-ABS is designed to (a) BS5400 : Part 2 : 1990 (b) BS8110 : Part 1 : 1997 | | ● | Hydrostatic pressure are eliminated by the provision of drainage system at the back of walls | | ● | Characteristic concrete cube strength at 28 days : Grade 40 | | ● | Concrete cover to reinforcement : 50 mm on inner arch face; 40mm on outer arch face | | ● | Minimum Fill Depth : 500mm | | ● | Backfill material : sand / suitable soil material approved by the Engineer with angle of internal friction not less than 30o | | ● | Soil-structure interaction approach is adopted in the structural analysis of the ARCH units |

Download PDF Brochure

Go to Top

|